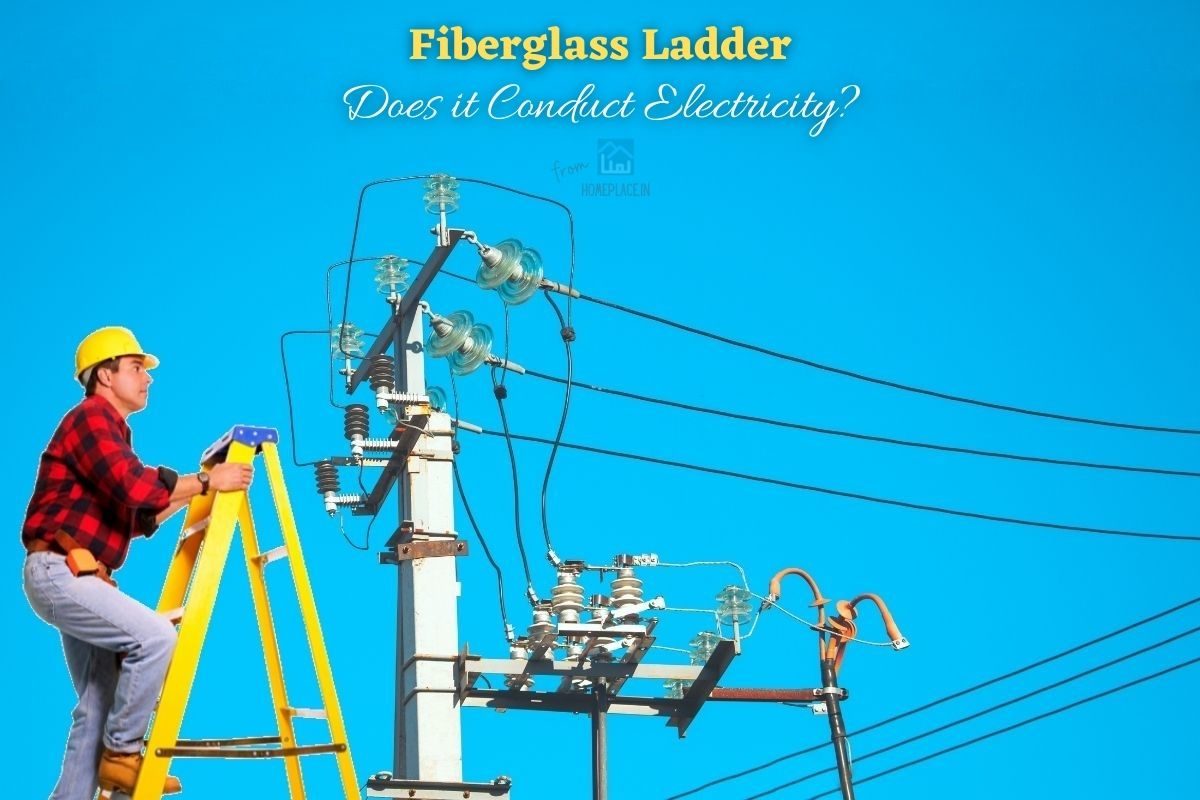

Electrical safety must be considered when working with a ladder on electricity transmission lines, an electrical circuit, or equipment. They come in a variety of shapes and sizes, as well as different materials- aluminium, fiberglass, wood, steel, etc. Always choose a non-conductive fiberglass ladder when working with electricity.

What is a Fiberglass Ladder?

Fiberglass is a material created from a polymer composed of a plastic matrix reinforced with tiny glass fibers combined with resin with around 100 Kg/m3 density. While many ladders are made entirely of fiberglass, others use fiberglass stiles and high-quality aluminum rungs to make them robust, lightweight, and long-lasting.

Both step and extension ladders fall within this category. Fiberglass step ladders have two locking arms on each side, allowing each leg to lock into place firmly, preventing them from closing again.

Fiberglass extension ladders are made up of two parts. The bottom has feet, and the top has plastic end caps or wings that secure it to the side of the building or pole. The top half of the ladder also contains two spring-loaded locking arms that link to the bottom segment’s legs. As you climb, these arms keep the top part from slipping back down.

Also Read: Step vs. Extension Ladder

Do Fiberglass Ladders Conduct Electricity?

Fiberglass is a non-magnetic insulating material that prevents electricity from flowing. It has zero electrical conductivity alongside a minimal 0.04 W/m.K thermal conductivity making it safe for electrical works.

Generally, fiberglass ladders do not conduct electricity, but, there are certain conditions which you should take care of while working with a high-voltage electricity transmission lines.

The non-conductive quality of fiberglass ladders can be nullified in two conditions, which most people are unaware of. The first one is due to dirt accumulation, and the resin polymer bonds begin to break down after the ladder has been exposed to UV light for a long time.

A closed-circuit will occur if the dirt develops a continuous “electric track” inside the fiberglass rails that links the rails or the earth to the rails and comes into touch with a live wire.

How can this happen?

Intense heat, excessive humidity, and chemical exposure can cause this condition. Fiber bloom is a phenomenon that occurs when the exterior coating and polymer are degraded as the glass fibers are exposed to the air.

This might lead to dirt accumulation in the crevices. In addition to metal, Ionic chemicals are the other principal conductors and can invariably be found in the dirt.

How to avoid it?

To avoid future damage from fiber blooming and dirt collection, clean the ladder with a suitable solvent, and apply a primer and appropriate protective coating.

If the ladder absorbs water, it should be heated for 4-12 hours in a circulating heat chamber at 49°C to evaporate the water. It will clean the grimes making the fiberglass ladder friendly to electricity works.

Related: Best Ladders in India

Advantages of fiberglass ladders

- The non-conductive qualities of fiberglass ladders are the primary rationale for their use. Fiberglass is ideal for individuals working near power lines since it does not carry electricity. While alternative non-conducive materials, such as wood, are available, fiberglass is more robust and lighter, making it simpler to maintain, handle, and transport.

- Because fiberglass is a high-quality insulating material, it is far more durable than natural-material access goods like wood. This improves the safety of fiberglass step ladders while also assuring their long-term endurance.

- Ladders made of fiberglass are flame-resistant with a heat capacity of 400 J/Kg.K.

- Fiberglass ladders are unlikely to bend and do not sag under heated conditions.

Limitations of fiberglass ladders

- Fiberglass ladders are heavier and costlier than aluminum ladders making them incompatible for home use.

- They need to be gel-coated to sustain the durability after using for several years.

- You must clean and maintain fiberglass ladders regularly to keep it safe to use.

alternatives to Fiberglass Ladders

- Wooden Ladder

A wooden ladder is the best alternative to a fiberglass ladder for electrical works. It is also cheaper and have lightweight compared to fiberglass. However, the wooden ladder must be dry because wet wood can conduct electrons.

On the other hand, a wooden ladder has some disadvantages too. The wooden frame can split or buckle at any time causing injuries like a splinter when used for a long time without proper care. Apart from that, the ladder’s rungs can wear quickly making it less durable than fiberglass ladders.

- Aluminum Ladder

Aluminum is a lightweight and cheaper material than fiberglass. An aluminum ladder can be transported easily from one place to another because it doesn’t have too much weight. Most importantly, it is resistant to any type of corrosion or moisture, making it easy to work with.

However, you should not use an aluminum ladder for electricity transmission works as they can conduct heat as well as electricity. While it is ideal for home use, no heavy-duty work should be attempted using an aluminum ladder.

- Steel Ladder

While steel ladders are best for heavy-duty, commercial and industrial usage, they are not ideal for working with electricity. Although this type of ladder is really heavy, they are durable.

The verdict

Do you seek a safe ladder for electrical works?

Maybe you have a fiberglass ladder or planning to get one and aren’t sure if it’s safe to use for electrical work. Ladders made of fiberglass do not carry electricity and acts as an insulator. As a result, they are the safest ladders to use when working near cables and electrical transmission lines.

Though there are a few shortcomings, we can significantly reduce the risks if we follow safety guidelines and only use ladders that fulfill all of the criteria. When working with electricity, using a fiberglass ladder is the best method to limit the danger of electrocution and maintain overall safe working conditions.