A sewing machine is probably the most reliable way to sew any kind of fabric. Besides professional usage, the best sewing machine in India can be an excellent addition for households to stitch fabrics effortlessly and flawlessly. Using this machine saves a lot of time compared to manual efforts and ensures the exact strong stitch.

But, to sew any fabric correctly, you need to have an ideal sewing machine needle as well. People often fail in delivering perfection in sewing only due to a lack of knowledge on finding a perfect needle. However, after going through this article, you will never fail in choosing a suitable sewing machine needle ever. It will provide all the necessary information regarding sewing needles regarding every minute considerable aspect. So, without seconds late, let’s dive in!

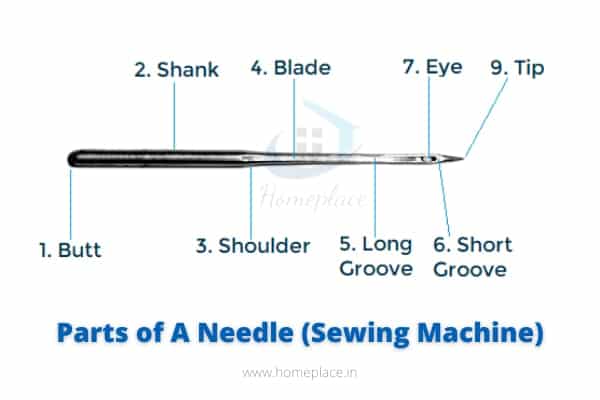

Parts of a Needle in A sewing machine

Before proceeding to the preferable sewing needles, it is essential to know about a needle’s parts. Thus, here is a clear-cut explanation of every part and its respective functions.

1. Butt

It is basically the bottom edge of the needle that helps attach the needle with the clamp or needle bar of the sewing machine. Butt is available in many shapes and sizes.

2. Shank

Shank is a flat of the cylindrical-shaped bottom part of the needle. It is tied in the needle bar and is more expansive than other elements to support the needle body.

3. Shoulder

The shoulder lies in between the shank and blade of the needle. It penetrates through the fabric when the needle reaches the lowest position. By doing this, it produces a wider hole and reduces friction between needle and fabric.

4. Blade

The blade is the longest part of the needle where maximum friction with fabric takes place. It is the part between the shoulder and needle eyes and is narrowed to the tip.

5. Long groove

Sewing thread takes place in this part during up and down movement in sewing time. It lies between the shoulder and the needle eye and reduces the friction, thus preventing any damage to the thread.

6. Short groove

Short Groove lies in the side of the needle where the hook is placed. It is placed between the needle’s eye and the tip, which helps sewing thread to create a loop.

7. Needle eye

The needle eye holds the needle thread and helps in creating the loop. It is situated between a long groove and a short grove in front of the needle. The inside edge of the needle eye plays a significant role in preventing damage to the thread.

8. Scarf

The scarf is a curved slot above the eye, which helps close the setting between needle and looper. It makes it easy to catch the needle loop by the hook.

9. Point/ Tip

It is the part from the tip to the needle’s eye, which helps the needle penetrate the fabric. It also prevents damages to fabrics, which is why needle quality is determined based on the point. Tip helps to create a hole in the fabric during sewing. It is the ending edge of the needle, which is essential to penetrate the fabric without any damages.

The following sewing machines are very durable and powerful enough to do regular tasks. All of these come with high-quality needles and the manufacturer enclosed proper instructions on how to use them.

Types of Needles for A Sewing Machine

The sewing machine needles are standardized since the beginning to be compatible across all brands of sewing machines. It is essential to know about different types of needles and suitable fabrics for each of them. It’s only the proper selection of sewing machine needles, which makes a sewing expert. However, we have listed the most popular sewing machine needle types and the fabrics for which they are used for.

Universal Needles

These are the most commonly used needles that can be used with woven fabrics, synthetics, and other knit fabrics. You can find both larger and more delicate sizes of needles in this type.

More delicate needles are used for lightweight fabrics, while larger ones are for medium to heavyweight fabrics.

Stretch Needles

Stretch Needles are used for fabrics such as Lycra, power net, or any elasticized synthetic fabrics. These have a scarf that provides extra room for the hook to pass quickly to prevent skipped stitches.

It is essential to choose the needle with tight tips as most stretch needles are difficult to use.

Ballpoint Needles

These are the perfect needles for most knit fabrics. Ballpoint needles are excellent to work on cotton knits, interlock, double knit and rib knits and fleece, etc.

The use of these needles on elastic fabrics prevents laddering or running due to stitching. Moreover, cotton blend threads or polyesters are the ideal applications for Ball Point needles.

Sharp Needles

Sharp needles are ideal to use on densely woven fabrics like silk and microfiber. These are specially designed to stitch multiple layers of fabrics due to the presence of a stronger shaft.

The shaft of these needles avoids bending or breaking the needles while the sharp point can easily penetrate. Furthermore, a short round threading eye is also provided to deliver more strength while sewing.

Quilting Needles

These needles possess a reinforced shaft, which makes it ideal for multi-layers of fabric and wadding as well. But, they are a bit shorter in length when compared to the sharp needles used for the same purpose. The shorter length makes the stitching easy and even too.

Jeans Needles

As the name suggests, denim jeans find the best application for these needles. These are also best for other densely woven fabrics such as canvas, heavy linens and heavy twills, etc. However, you should choose threads like synthetic, blends, 100% Polyester, and cotton wrapped Polyester and heavy topstitching threads, etc.

Leather Needles

These are also known as chisel point needles as they look and act as chisels while using. Leather needles find most applications in genuine leather or suede. But, these should not be used on a few fabrics such as ultra suede and synthetic suede.

Metafil Needles

Metafil needles possess a large needle eye due to which even thick threads can feed through it quickly. These needles are ideal for general sewing purposes and can be a good buy due to the large eye. You won’t need to struggle to thread your needle anymore with these needles.

Embroidery Needles

These needles come with a wide eye for threads like Polyester, Rayon, or Cotton machine embroidery threads. Embroidery needles also possess a pontoon scarf with a large bump, which reduces the chance of missed stitching.

Top Stitch Needles

Topstitch needle comes with additional sharp points that can easily penetrate through all fabric types. These needles also possess a large eye as well for topstitching threads.

Twin & triple Needles

These needles are mostly used for decorative and tucking stitches. They should be used for low speed and fits only specific machine types.

Wing Needles

Wing needles are used for unique stitch options on machines. They produce holes in the fabrics for specific thread works. However, you can find individual natural fibers like cotton to use with these needles.

We have found the following needle set to be very useful with most of the sewing machines available in the market. It includes sets of 11,14,16,18 number needles with a total of 40 needles.

Ideal Needle Size for sewing machines

You may have come across needles with numbers on it like 110/18 or 80/12 and wonder about their use. Well, from now, you will select your sewing machine needle with these numbers only. The small number is the American needle range system, while the larger numbers are of the European system.

European needle sizes range from 60 to 110, whereas the American model’s needle size range is 8 to 18. Typically, 80/12 needles are used for stitching dresses and come with most sewing machines. However, one should go through the reference chart for complete information about the sizes.

Apart from considering the chart, one can also consider the needle eye’s size while buying a sewing machine needle. The needle eye’s length and inner texture determine the hands’ quality besides being convenient to thread. Thus, testing the texture is the safest means to buy a sewing machine needle.

How to find the Right Size of Needle for sewing machine?

A needle with a smooth texture inside the eye of the hand prevents the damage of thread. Having a wide eye makes it easy to pass the thread through the needle without needing magnifying glasses or concentration. But certain universal factors can simplify your selection to some extent. These factors are universally required for all kinds of needles.

You can choose the appropriate needle sizes for your sewing machine by considering two essential factors, they are-

- The Thickness of a Needle: The size of the needles generally varies with the thickness of the needles. Thinner needles are suitable for delicate fabrics such as chiffon, while thicker needles are for dense fabrics.

- Purpose of the Needles: The purpose of stitching also determines the size of the needles. If you need to sew stretch fabrics, denim jeans for topstitching, you should go for bigger sizes. On the other hand, dense woven fabrics and leather required sharp and specially shaped tips to penetrate through them.

However, the numbers on the sewing machine needles represent the thickness of the fabrics. Thus, different numbers are given for different materials. If the number is more extensive, you can sew thicker or denser woven fabrics with the needles. On the other hand, a smaller number is for sewing more delicate fabrics.

Sewing Machine Needle Chart (For Size and Use)

| Sewing machine needle sizes | The size of needles (European) | The size of the needles (American) | Type of fabrics to use | Type of threads to be used |

|---|---|---|---|---|

| Universal Needles | 110 | 18 | Upholstery, heavy Denim, heavy canvas, and Extra heavy fabrics | Extra Upholstery Thread |

| 100 | 16 | Upholstery and heavy fabrics | Sew-All and Extra Upholstery Thread | |

| 90 | 14 | Linen, Medium to heavy fabrics and calico, etc | Sew-All and Extra Upholstery | |

| 80 | 12 | Light wool, poplin, Shirting, and rayon, etc | Sew-All | |

| 70 | 10 | Delicate silk, voile, and sheers, etc | Sew-All | |

| Sharp Needles | 90 | 14 | Top Stitching | Sew-All |

| 80 | 12 | Microfibre, Shirting, etc | Sew-All | |

| 70 | 10 | Microfibre, Voile | Sew-ALL | |

| Ball Point Needles | 90 | 14 | Double knit and Medium heavy knits | Sew-All |

| 80 | 12 | Lacoste and Interlock | Sew-All | |

| 70 | 10 | Tricot and Light knits | Sew-All | |

| Stretch Needles | 90 | 14 | Heavier Lycra, Elasticized fabrics, and all elastic fabrics | Sew-All |

| 75 | 11 | Elasticized fabrics and Light Lycra | Sew-All | |

| Jeans Needles | 100 | 16 | Heavy Denim, furnishings, and vinyl | Extra Upholstery |

| 90 | 14 | Tightly woven fabrics and Denim | Extra Upholstery | |

| Leather Needles | 100 | 16 | For leather but not for synthetic leather | Sew-All and Extra Upholstery |

| 90 | 14 | Suede and all leather | Sew-All and Extra Upholstery | |

| Metafil Needles | 80 | 12 | For decorative sewing on many different fabrics | Delicate rayon decorative threads |

| Quilting Needles | 80 | 12 | For quilts made from wool, Polyester with wadding center, cotton, etc | Natural Cotton |

| Embroidery Needles | 90 | 14 | For decorative sewing on only heavier fabrics | Polyester and Rayon Embroidery Threads |

| Embroidery Needles | 75 | 11 | For decorative sewing on lightweight fabrics | Rayon Embroidery Threads |

| Twin Needles | Available in various sizes | Available in various sizes | For decorative sewing on several fabrics | Needs two threads |

How to thread a sewing machine?

Now that you are familiar with the sewing machine needles’ types and sizes, we can proceed further. One of the most complicated things about the sewing machine is fixing the threads. But it will not be a problem for you anymore as we are going to shed light on how to thread a sewing machine.

You will indeed be a master in threading a sewing machine after the completion of this section. So let’s start with the guide to thread a sewing machine.

Things to do before starting

- Choose the type and colour of the thread that you have to use.

- Wind the Bobbin with the chosen thread

- Make sure to choose a good quality thread with a proper winding for top usage

- Going through the sewing manual that comes with the machine can be of great help (this if for modern machines with a slightly different approach)

10 Steps to Thread a Sewing Machine Needle

If you have cross-checked all those things mentioned above, you are ready to get into threading a sewing machine. Here are the steps to be followed-

Step 1 – Placing cotton on top spool

You can find a spool at the top of the machine. Put the thread winding on the spool. This spool’s placement depends on the machine’s build, whether it is an upright peg or lying down.

Some machine comes with a plastic disc to place on the spool. This disc holds the spools and prevents flying off after sewing starts.

Step 2 – Passing through thread Guide

Every sewing machine comes with a thread guide that leads the direction of the thread from the spool. It is often present beside the top spool.

Place the thread through the guide by pulling some of the thread from the winding. The size of the guide varies from one machine to another.

Step 3 – Looping thread through tension knob

The tension disc is present right below the guide to lead the thread downwards. Pull the thread down towards the knob and loop it around the discs.

Step4 – Passing through the Second thread guide

Now, pull the thread back up again following the ridge as it creates a U shape. The second thread guide will also have a lever with an eyelet, which is termed as a “take-up lever.”

Step 5 – Follow Needle hook

Now, bring the thread down to the needle after crossing all hooks until the needle is reached.

Step 6 – Thread the Needle

Thread the needle after passing all the hooks. But remember, you should insert the thread from the front to the back. You can also follow some expert tips to thread the needles correctly.

Step 7 – Insert Bobbin

Now you can wound your Bobbin based on Bobbin’s type. You can follow the manual instructions for winding and inserting the Bobbin. Some bobbins also have a removable case in which you can insert the bobbins. If there are no such cases, you can drop the thread straight down into a fixed position.

To wind the Bobbin, you have to turn the big wheel on the right side forwards. The needle hooks up both the top and bottom threads. You have to just bring the thread from the Bobbin to the top plate where the needle is placed.

Step 8 – Join Bobbin with the top thread

You can find the loop from the thread coming from Bobbin. This loop is the one that is pulled out to the top. You can use tweezers to grab the loop to the top of the plate.

Step 9 – Pull the thread backward

Now that the bobbin thread meets the top thread, you have to pull both of them backward. Make sure that both the threads are running freely while hauling them to the back.

Step 10 – Ensure proper thread

To ensure that the threading procedure is done correctly on the machine, verify it on a piece of scrap fabric. You can pick up a small piece of futile fabric to demonstrate the thread’s stitches and tension.

While testing, you should hold the threads that are laid to the back. In this way, you can ensure that both threads don’t tangle up with each other. Also, keep in mind to lower the foot to make the fabric steady and connect with the feeder procedure.

Although these steps are common in most sewing machines, you can surely use some extra tips to get mastery in threading a sewing machine needle. With this, you can be assured of mastering how to thread a sewing machine from all aspects.

Threading a Sewing Machine using magnifying glass

Various sewing machines come with a magnifying glass attached right above the needle placement. These glasses can simplify the needle threading procedure to a great extent.

You can use a pair of glasses specially designed to enlarge things. These are nothing but magnifying glasses attached to the frame. But, usage of these glasses is limited to needle threading only. But if you don’t want to get either of these tools, you can proceed with the following steps.

- The best way to pass the thread from the needle eye is to trim the thread’s end with sharp scissors.

- You can also wet the thread’s end so that the extra hairs join the bulk of thread. A moist line is way more accessible to the thread when compared to the dried ones. A lick of lips or even a wet touch with fingertips can simplify the needle threading.

- Concentrate extra light on the needle so that the needle eye can be clearly visible to the eyes. Most modern machines come with extra light fitted, but even the flash of a Smartphone can be of great use.

- You can also find many little gadgets online. These can be narrowed tweezers or specially designed tips to pull out the thread from surpassing the needle.

Conclusion

By now, you indeed have gained enough knowledge to thread the sewing machine. Not only those conventional aspects but now you are also the master in selecting the size and type of needle for different fabrics. So, you are on your way to become a professional in sewing and stitching. Now, all you have to do is practice the threading and sewing procedures to work on anything. However, you can also go through the expert guide for handling the fabrics on the sewing plate.

Furthermore, you should also choose a sewing machine from reputed manufacturers. Having convenient technology in the device can simplify your sewing operation to a great extent. Additionally, you can also find sewing machines with advanced tweaks and perks to make your work more accessible than ever. The best way to choose a convenient model is to prefer the online market.

Related Posts: