Have you considered the necessity of purchasing a water heater?

During the winter, you might need a lot of hot water for bathing, cleaning dishes, and so on.

When you go to the store to buy a water heater, you are likely to confuse about which one to buy. There are a variety of alternatives available, and you’ll need to be well-versed in-tank coatings and materials.

The purpose of buying a water heater, as we all know, is to store hot water. This water would then be used as and when it was required. Depending on the utility, the storage duration might be 10 minutes or even an hour.

The most significant thing is that you’ll need to seek a decent water heater that won’t rust in these conditions. You should also choose one that has the input water supply in place at all times. As a result, such water heaters would constantly be full of water.

How Good Quality Coating And Tank Materials Affect The Performance Of A Geyser?

Water heaters, often known as geysers, have become a necessity in most Indian homes. Many of us feel uncomfortable taking a shower with cold water during the winter season. This is when the water heaters come to our rescue, providing us with the joy of warm water amid the frigid winter air.

But, before we get into geysers, it’s vital to understand what qualities a geyser must have so that it can be a better deal for you. The water heater should be energy efficient, have enough capacity for your household, heat water fast within a few minutes, and include safety measures.

As we all know, there are many brands and product lines on the market, making it difficult to decide what to buy. So, if you want a stylish and high-quality water heater or geyser, you’ve come to the correct spot. The following essay attempts to assist you in making a more informed decision.

We’ve put together some well-researched information on water heaters, as well as a list of the best instant water heaters available in the market.

What Is an Inner Tank? Why Is Its Material Important?

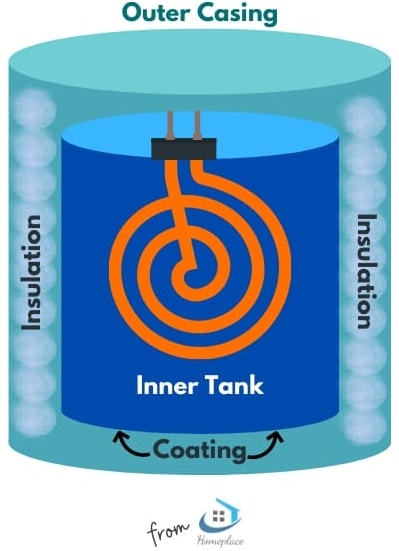

A water heater’s inner shell is a big metal tank with a water-resistant liner that can store 40 to 60 gallons (151 to 227 liters) of hot water at 50 to 100 pounds per square inch (PSI), which is within the pressure range of a standard home water system.

The storage tanks of water heaters are typically made of four different types of materials. They are as follows:

1. Stainless Steel

The most often utilized material for tank liners is stainless steel. Stainless steel will be required to build tanks for cargoes that are very corrosive to mild steel, such as sulphuric acid, or cargoes that require high purity requirements (wine or fruit juice).

One of the most significant components of stainless steel is chromium oxide. It is the development of a passive surface layer that gives Stainless Steel its corrosion resistance. When the metal is exposed to air or water, this coating develops spontaneously.

The corrosion resistance of the stainless steel is at its highest levels. When the film is damaged, and the passivation methods are followed correctly, the stainless-steel surface generally re-passivates. Stainless steel has this characteristic, which makes it a better choice than coated steel.

Advantages of Stainless Steel Inner Tank

- Corrosion Resistant: Because stainless steel resists corrosion, it’s an excellent choice for water heater tank material.

- Low Maintenance & High Value: Because stainless steel fasteners do not accumulate scratches and rust like other fasteners, they usually minimal maintenance. Because of its durability, you’ll be able to save money on fastener replacement.

Limitations of Stainless Steel Inner Tank

- Need to Be Properly Fastened: If you use stainless steel fasteners, ensure they are correctly fastened with spacers to avoid metal-on-metal corrosion.

- Slightly More Expensive: Stainless steel, as previously said, is generally slightly more costly than other materials. As a result, outfitting your entire project with stainless steel fasteners might be expensive.

2. Copper

Copper is corrosive by nature, yet the metal is a strong heat conductor. It causes heat loss, which we cannot afford when using the heater. It necessitates the application of an anti-corrosive coating. Because copper is used to make storage tanks, a coating is required.

Copper tubing is often used in new and refurbished buildings for heating systems. Engineers have discovered that copper tubing is still superior to any alternative material when all considerations are considered. Lightweight, various tempers, long-term dependability, and simplicity of connecting, bending, and handling are all significant advantages.

Advantages of Copper Tank

- One benefit is that it is an excellent conductor since many electrons carry the flowing current.

- Another benefit is that copper is malleable, which means metal may be hammered or bent indefinitely. Copper mining has several environmental effects, including erosion, sinkholes, biodiversity loss, and soil erosion.

Limitations of Copper Tank

- Copper has the drawback of being expensive since it requires a lot of energy to excavate the ore and extract copper.

- It also has the drawback of being non-renewable due to its inability to be grown or manufactured.

- Finally, another disadvantage is that it is readily broken. Even though we believe that copper is the sole good metal, we know that it has certain advantages and downsides.

3. Mild Steel

Mild steel is a ferrous metal made of iron and carbon. It’s a low-cost material with properties that make it suitable for a variety of technological applications. Low-carbon mild steel has significant magnetic properties due to its high iron concentration and is classed as ferromagnetic.

Mild steel has a minimum carbon concentration of 0.16 percent and a maximum carbon content of 0.29 percent, with a melting point of 1450°C to 1520°C. Steels with a higher carbon content have a lower melting temperature than mild steel.

Advantages of Mild Steel Tank

- It is lightweight: The amount of carbon in steel can affect its weight. For example, carbon steel (steel with a high carbon content) is significantly heavier than mild steel since mild steel contains less carbon than carbon steel. As a result, if you choose mild steel, you will be able to operate independently. Choosing heavier steel kinds may need enlisting assistance in carrying the metal while you work.

- It is affordable: Mild steel is one of the most cost-effective steels. Because of its low cost, this material is perfect for those looking to keep project expenses as low as possible.

Cons of Mild steel tank

- It cannot be heat treated: Steel’s carbon content is frequently affected by heat treatment. Heat treatment is commonly used to change the properties of steel, such as making it more challenging. As a result, mild steel is a poor choice for heat treatment due to its low carbon content, which prevents it from showing substantial changes following heat treatment.

- It isn’t very strong: When used in high-stress applications, such as making grates driven over often by large vehicles, mild steel will readily fail. As a result, it’s only appropriate for low-stress applications like creating home or garden items. This is in contrast to stronger steel, such as carbon steel, which can withstand high-stress environments.

4. Thermoplastic Polymer

Amorphous and crystalline thermoplastic polymers are two types of thermoplastic polymers. Because this sort of structure is more resistant to chemical assault by field, hydraulic oil, and paint remover, most thermoplastics suited for use as a matrix for high-performance composites have some degree of crystallinity.

Polymers are categorized as thermoplastics or thermosetting based on their behavior at high temperatures. The linear and branching architectures of thermoplastic polymers soften when heated and stiffen when cooled.

Properties of Thermoplastic Polymer

- Glass fibers are used in polyamide polymers to reduce brittleness. The material’s tensile strength is raised by a factor of three, and the heat deflection temperature rises from 150 to 500 degrees Fahrenheit.

- The physical characteristics of polycarbonate compounds have been substantially improved with 10, 20, 30, and 40% glass fiber loading.

- Polyphenylene sulfide, polypropylene, and polyethersulfone are among the polymers that benefit from including glass fibers.

Benefits of Thermoplastic Tank

- Thermoplastics save energy in both their production and processing.

- Thermoplastic components may be produced in large quantities with great accuracy and at a reasonable cost.

- Most thermoplastics outperform metals in terms of characteristics, and they can withstand greater deflections without deforming.

- The thermoplastics may be remolded and recycled without altering the physical characteristics of the material.

- When heated, they soften, and as more heat is given, they become more fluid.

Limitations of thermoplastic polymer tank

- Under intense pressure, many thermoplastic materials, particularly composites, prefer to fracture rather than deform.

- When thermoplastic materials are subjected to long-term stress, they experience creep, which causes them to relax or weaken.

- When exposed to direct sunshine or UV radiation for long periods, some thermoplastics deteriorate.

Why is A Protective Coating on The Tank Necessary?

The protective coating put on the interior and outside of a water storage tank is its primary defense against corrosion, which may progressively degrade the tank and potentially harm its contents.

Coatings are important for preserving what’s inside the tank and ensuring that the owners of this expensive equipment get the most out of it.

Regular inspections by certified water storage tank inspectors specializing in coatings are required since the protective coating is the most likely component to fail. This allows them to examine the coating state and detect present and potential coating problems.

Best Coating Materials Used on Heater Tank

Most water heater manufacturers will use common materials such as copper, stainless steel, and thermoplastic for storage tanks. Now because copper is the best heat conductor, this would result in heat loss. Stainless steel, on the other hand, maybe the greatest alternative for offering superior insulation.

However, both stainless steel and copper are corrosive, necessitating the use of an anti-corrosive coating. The best non-corrosive material is thermoplastic; nevertheless, it does not have the best insulating characteristics. This means that storage tanks constructed of stainless steel would be the ideal option for any anti-corrosive and insulating needs.

1. Glass lining Coating

As we all know, glass is a poor conductor of heat. As a result, when you combine glass with stainless steel, you will obtain excellent insulation.

The glass is placed directly into the powdered material on the storage tank liner. When heated to a particular temperature, the powdered glass fuses with metals to form an anti-corrosive coating.

2. Enamelled Glass lining Coating

Enamel glass lining coating includes an extra coat of enamel materials on the glass-coated tank. Here are the three types of enameled glass lining coatings for water heaters-

Porcelain Coating

A cutting-edge European technology, Porcelain, was brought to India for the first time a few years ago. The porcelain enamel looks like glass here. For the mechanical bond with the metal substrate, it has a fused coating at 830 degrees C.

This would now make the vitreous enamel layer more durable and easier to install. This would be filled with corrosion-resistant steel to protect the underlying steel and keep you safe from rust. Regardless of the water quality, the glass-lined tank would continue to function properly for many years.

Vitreous Enamel Coating

The vitreous enamel coating is strong and easy to work with. That would protect the steel from all types of rust and corrosion. Not only that, but the glass-lined tank would function flawlessly for many years, regardless of the water quality.

This approach might be used to coat the water heater tank with a liquid vitreous enamel coating material. After that has been cured, the furnace may be fired to create the glazed enamel interior coating.

Blue Silicon Coating

The following baking at 870°C in the furnace would result in a flawless glass lining on the tank. It would also provide an ultra-hygienic surface inside the tank, assisting in preserving the water’s purity. As a result, the tank’s lifespan will be extended.

After the inner tank coating, every electric geyser has a filler material that helps to withstand the temperature by not allowing the heat to escape easily. Glass wool and PUF (Polyurethane Foam) are the most common materials to fill the gap between the inner tank and the outer casing.

What Materials Are Suitable For geyser Outer Casing (Body)?

The outer casing of a water heater must be durable and have a high capability for heat resistance. Manufacturers use mostly these three materials to build the outer body of the geyser-

1. Polymer

Polymer is a broad word that encompasses plastic, wood, rubber, and other materials. Polymer materials are used in the heating chambers of more than half of the water heater manufacturers on the market. This material has a reduced cost, which translates to cheaper pricing and more savings for the consumer.

ABS is the abbreviation for Acrylonitrile Butadiene Styrene. Let’s boil that down into some more basic words because it’s quite a mouthful. Acrylonitrile Butadiene Styrene is a thermoplastic polymer, a very versatile kind of plastic utilized in various applications.

Thermoplastic polymers are valuable because they become flexible when heated and solidify when cooled. As a result, thermoplastic polymers such as ABS plastic are commonly utilized in the injection molding process.

2. Powder-Coated Steel

Powder coating is a polyester-based coating that employs dry polyester microbeads of uniform size. The beads have an electrical charge that allows them to stick to a variety of surfaces.

Powder coating, as opposed to painting, produces a harder, more lasting, and more robust surface ideal for items that must withstand harsh weather conditions or give years of reliable service. Today, many solar water heater brands use powder-coated steel as the outer casing material.

The procedure of applying powder coating differs from that of applying paint or other coatings. Because liquid forms are more sticky than dry forms, most coatings are applied as liquids. For example, liquid paint is applied as an evaporating solvent.

3. CRCA (Cold Rolled Close Annealed Steel)

This is a steel grade in which the thickness of the steel is reduced by cold rolling after hot rolling and pickling. Manufacturers harden the material by cold rolling. After that, the cold-rolled steel is annealed in a sealed container with nitrogen or other non-oxidizing gases to soften it and protect it from oxidation. CRCA is the most preferable outer casing material used in the best gas geysers for home and commercial use.

The cold rolling technique is required for producing steel sheets with a thickness of less than 1.6 mm. These applications for low-thickness cold-rolled steel sheets necessitate a noble surface quality, whereas hot-rolled steel has a rough surface with pits and other imperfections.

Tank Materials And Coatings Of Water Heater – Conclusion

It may be inferred that the water heater you will buy should have greater insulation and a higher quality anti-corrosive coating on the interior. The finest water heaters have a stainless-steel storage tank with anti-corrosive glass or polymer coatings.

Most water heater manufacturers provide a warranty on both the overall equipment and the storage tank. The warranty duration is a reliable measure of the storage tank’s durability. Water heaters with superior corrosion-resistant storage tanks will often have a longer warranty duration. As a result, when purchasing a water heater, you must verify both the overall guarantee and the warranty on the storage tank.

Finally, you will choose the Water Heater that is within your budget and has a longer warranty duration than the others, even though there are several alternatives on the market. You should be able to acquire one of your options without difficulty.

Related Posts: